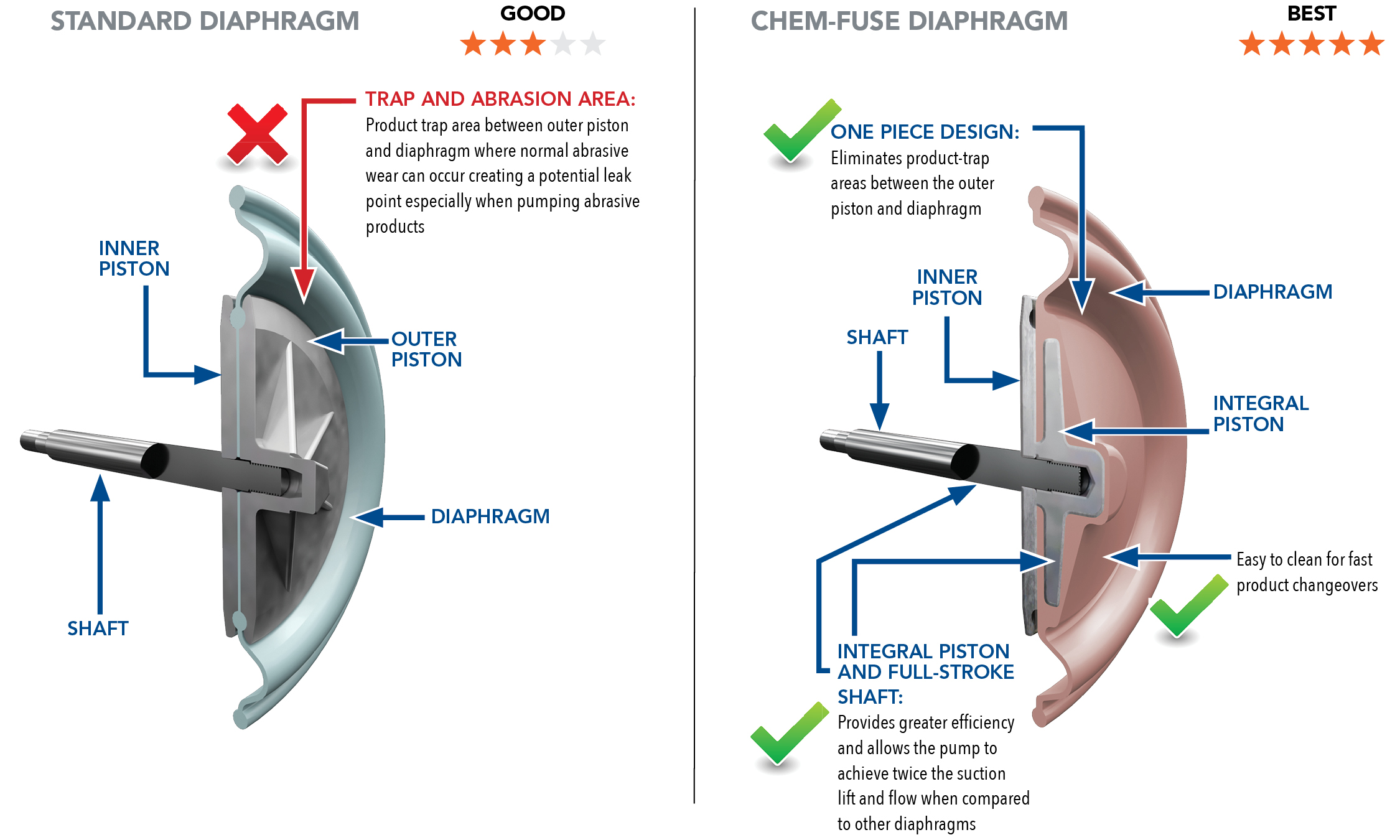

Since their invention, the standard diaphragms in air-operated double-diaphragm (AODD) pumps have had one hard-to-overcome drawback: there was a natural wear spot between the outer piston and the diaphragm itself. It was there that normal abrasive wear would occur, and this abrasive wear was the primary cause of diaphragm failure, regardless of the type of diaphragm material used. This would create problems for the user from a lost product, maintenance and replacement perspective.

Additionally, the outer-piston design could lead to the buildup of the pumped liquid, especially if it is an adhesive. In this case, the adhesive substance could collect on the outer piston because of the outer piston’s flat shape that features pockets or areas where adhesive-type fluids can nest or be trapped. Another potential problem can occur when the thickness of the material buildup’s “skin” reaches a certain level and it shears off during the pumping process. Any buildup that enters the liquid stream can damage the pump or get stuck in the production system, which can lead to debilitating breakdowns, downtime and prohibitive repair/replacement costs.

Well, outer-piston abrasion and product trapping can now be a thing of the past as Wilden® has found a solution in its patented Chem-Fuse Integral Piston Diaphragm (IPD). The true genius of the Chem-Fuse IPD is a patented one-piece design that eliminates product-trap areas between the outer piston and diaphragm. Also, the IPD design makes Chem-Fuse diaphragms easy to clean for fast product changes, while an integral piston and full-stroke shaft provide greater efficiency and allow the pump to achieve twice the suction lift and flow when compared to other diaphragm models.

Additional features of Chem-Fuse diaphragms include:

- Up to 100% increased flow and suction lift compared to other reduced-stroke IPD diaphragms

- Wil-Flex construction, which makes them 50% less expensive than PTFE-laminate diaphragms

- Compatibility with Wilden’s Pro-Flo® SHIFT bolted metal and plastic pump models

- Available in Wil-Flex™ (Santoprene®) and non-food-grade Saniflex™ (Hytrel®)

- Size availability from 25 mm (1"), 38 mm (1.5"), 51 mm (2") and 76 mm (3")

- Operational temperature ranges from -40ºC to 170ºC (-40ºF to 225ºF)

- Availability of high-pressure models for use with Wilden H800 model AODD pumps

All these features allow Chem-Fuse diaphragms to outperform standard diaphragm designs and deliver an elevated level of pumping performance, which makes them ideal for high-volume chemical and industrial liquid-handling applications. Most significantly, elimination of the potential leak point at the outer piston makes Chem-Fuse diaphragms the best choice when the application involves the transfer of critical, abrasive and/or hazardous liquids.

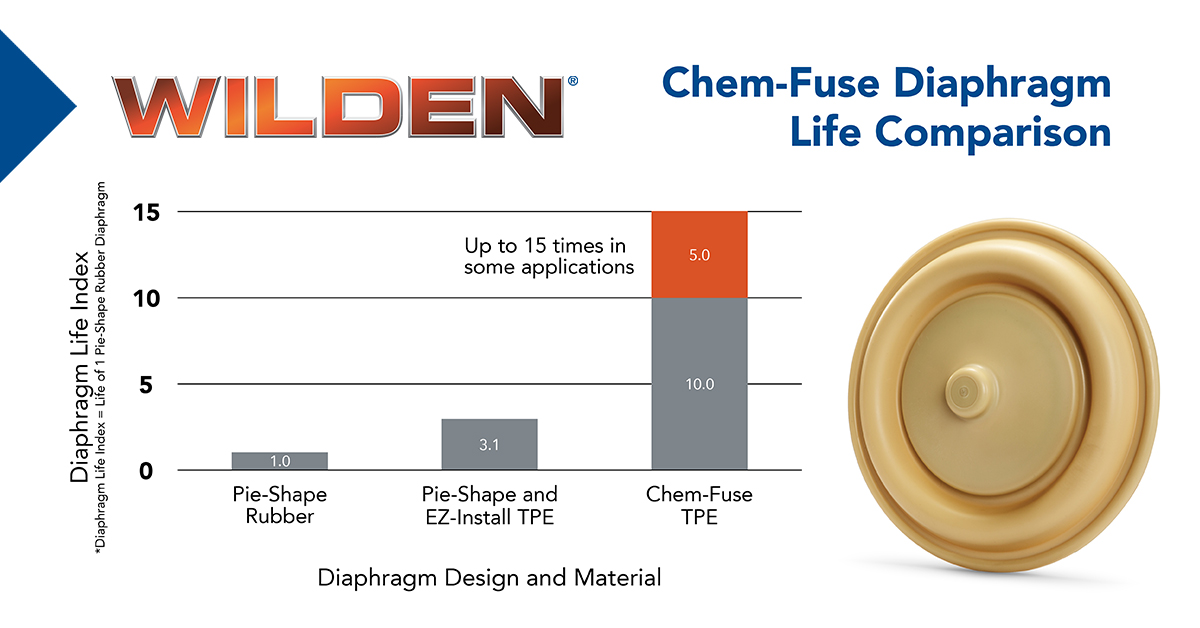

Additionally, the innovative design features and benefits of Chem-Fuse allow them to last three times longer than traditional conventional diaphragms, leading to unprecedented savings in maintenance and system downtime. To see the potential savings for yourself, visit the Chem-Fuse Savings Calculator today.

Learn more about Chem-Fuse Diaphragms here.